PEB Shed Manufacturer

PEB (Pre-engineered Building) Shed Manufacturer are a concept for buildings that have prevalent ordinary creation, tall auxiliary quality, and conservative plan. It brings down the strain on the establishment, which too brings down the cost of gracious development.

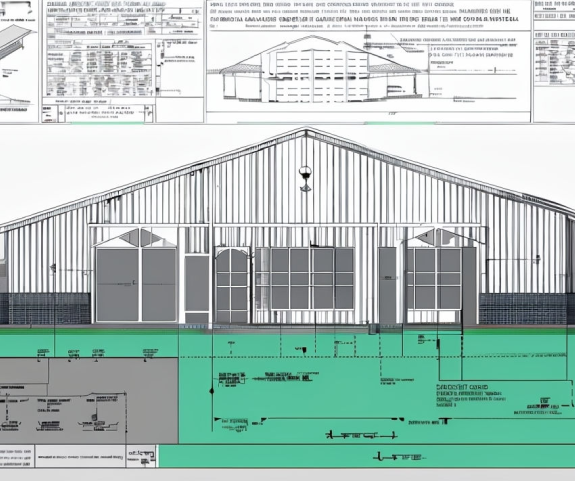

A PEB (Pre-Engineered Building) shed is a company that plans, manufactures, and supplies pre-fabricated building structures, counting sheds, stockrooms, and mechanical buildings. These structures are regularly made of steel and are outlined to be simple to collect and dismantle.

Pre-engineered buildings (PEBs) are shapes of developments that are planned in-house by PEB providers or PEB Shed Manufacturer producers. After development of PEB components, they are transported to an get together location and are congregated/set up at the location itself. A few pre-assembled components incorporate metal system, metal bars, wooden floors, process segments, metal rooftops, etc.

The number of PEB companies in India is on the rise since of the expanding request for PEBs which offer expanded adaptability, solidness and versatility in comparison to conventional developments. A few of the well-known PEB Shed Manufacturer structures incorporate work sheds, porta cabins, canopies, fire elude stairs, etc.

How Pre-engineered building manufactured?

Pre-engineered Buildings As the title infers, it includes the pre-engineering of auxiliary parts. PEB Shed Manufacturer supplies parcels that shift in length depending on the necessity. These are steel-framed industrial facilities that are welded together on-site. It can effectively be extended afterward by basically including inlets. Its high-quality portray framework guarantees amplified solidness and small support. PEBs are ordinarily utilized for mechanical, commercial, and regulation buildings, such as stockrooms, manufacturing plants, schools, and retail buildings. PEBs are regularly utilized for mechanical, commercial, and regulation buildings, such as stockrooms, manufacturing plants, schools, and retail buildings. They can too be utilized for foundation ventures such as airplane terminals, bridges, and railways.

Pre-engineered buildings (PEBs) are structures that are outlined, fabricated, and amassed off-site, ordinarily in a production line, utilizing progressed fabricating methods and innovation. PEBs are developed utilizing pre-fabricated components that are gathered on-site, coming about in a quicker, more effective development prepare compared to conventional development strategies.

PEB Sheds are commonly used for various purposes, such as:

- PEB Shed Manufacturer constructions are utilized for making houses, Working spaces, distribution centers, storages, manufacturing plants, stadium structures, railroad auditoriums, cold capacity spaces and indeed shopping centers.

- They are made utilizing steel bars and columns that can be formed agreeing to the necessities.

- Sheds are utilized to store domestic and plant apparatuses and hardware such as grass tractors, and planting supplies.

- In expansion, sheds can be utilized to store things that are not reasonable for indoor capacity, such as petrol (gasoline), pesticides, or herbicides.

A few of the key highlights of PEB Shed Manufacturer sheds are given below:

- Colors and wraps up: Pre-painted steel is passed on advanced high-speed coil delineate lines where the surface organizing a few time as of late portrait and paint curing is done on an essentially robotized line underneath culminate conditions.

- Mezzanine Framework: The mezzanine framework is an enveloping framework that comprises a dim deck supported by joists enveloped into basic mezzanine beams.

- Sheeting and Cover: the sheets made of steel are more habitually than not galvanized profile sheets that are until the conclusion of time color coated. Sheets are in expansion coated with unprecedented paints for overwhelming anti-corrosion properties. These are guarantees through cover pieces and the steel sheets are settled on beat of it as texture steel sheets.

- Crane Framework: Crane framework is utilized to move forward surface taking care of adequacy permitting more utilization of space by reducing development due to forklifts. The runaway columns of the crane are backed by built-up zones with the cap channels.

- Purling, girts, campve Struts: These are the partner cold-formed individuals of the components of the PEB Shed Manufacturer. In this course of activity, no welding is required. They are organized by welding the steel coil in organize to allow it the required shape. The Z-shape is for purl purling girts and the C-shape is for eave struts.

Focal points of PEB

Pre-engineered buildings have a number of focal points and these points of interest decrease the development time. The distinctive points of interest are as follows,

- Pre-engineered buildings are a foreordained stock of crude materials. It has fulfilled a wide run of auxiliary and tasteful prerequisites. The components are built already and are standardized. To utilize of customized computer program for plan and drafting diminishes the speed of the project.

- The plan time of the PEB Shed Manufacturer is decreased since they are shaped of standard areas and associations. The low-weight adaptable outlines offer higher resistance to seismic forces.

- Due to the entry of the frameworks approach, there is a sparing in plan fabricating and location erection taken a toll. The auxiliary charts are molded in such a way that they take after the push chart and in this way diminish the taken a toll, weight and stack to foundations.

- The pre-engineered buildings are around 30% to 35 % lighter than the routine steel structures. The establishments of PEB Shed Manufacturer are made up of straightforward plans and are simple to build with lighter weights.

- In the case of PEB Shed Manufacturer, the buildings can be effortlessly extended in length by including extra narrows to them. The development in width and stature is conceivable if you pre-design for future expansion.

- The associations of all the components utilized in a PEB Shed Manufacturer are standard and hence the erection time is faster.

- The quality control in the case of PEB Shed Manufacturer is completely guaranteed since the buildings are fabricated totally in the plant beneath controlled conditions.

- The paint frameworks are of tall quality for cladding and steel to suit the surrounding conditions at the location. This comes about in long toughness and moo support cost.

- The total building bundle of the PEB Shed Manufacturer is provided by a single seller. Hence, the compatibility of the building components can be completely assured.

- PEB Shed Manufacturer has the capacity to persevere the most grounded of storms. It has the most elevated toughness. These buildings come with the best guarantees in the industry.

Disadvantages of PEB:

- If not legitimately kept up it can be helpless to corrosion.

- Steel, in spite of the fact that a great conducting metal, diminishes the warm consolation of the building.

- This sort of building gets to be more helpless to fire and harm due to its conductivity.